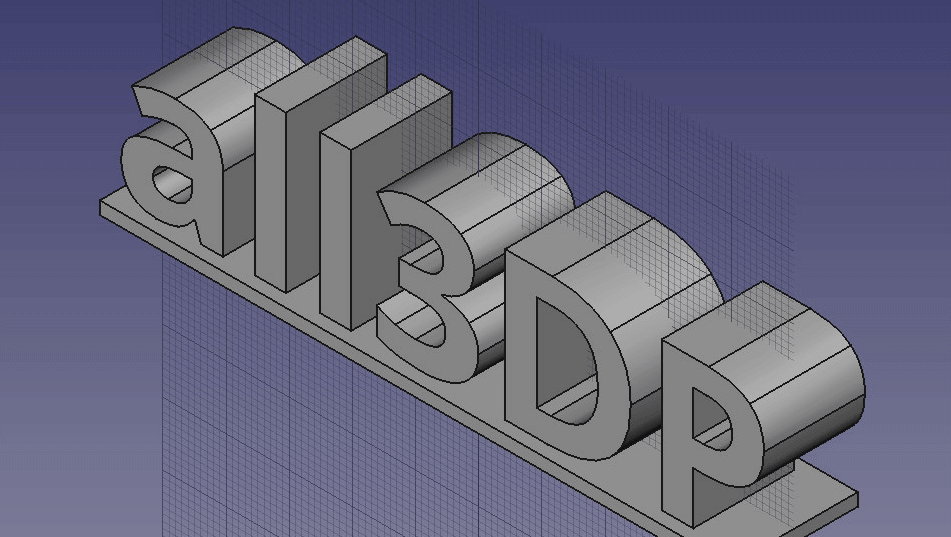

shows a cross-section of his FreeCad design, sharing the dimensions he has found to work best. The main components of this trick seem to be the shape of the place where the print will fold, and the alignment of bottom layer lines perpendicular to the direction of the fold lines. On Twitter, Chris shows off his foldable 3D print experiments ( nitter) that work around the support problem by printing the part as a single piece able to fold into a block as soon as you pop it off the bed. Over time we’ve learned to dial our settings in so that, hopefully, we don’t have to fumble around with a xacto knife after the bed has cooled down. Strategic offsetting, chamfering, and filleting are firmly in our toolkits. When designing even a reasonably simple 3D-printable part, you need to account for all the supports it will require to print well.

The chip also handles the whole TCP/IP stack internally, so only needs an external SPI interface to talk to the host device.Ĭontinue reading “Ethersweep: An Easy-To-Deploy Ethernet Connected Stepper Controller” → Posted in Arduino Hacks Tagged arduino, atmega328, freecad, KiCAD, network, python, stepper motor, udp, wiznet The hardware side of things is taken care of with the Wiznet W5500 ethernet chip, which implements the MAC and PHY in a single device, needing only a few passives and a magjack to operate. The thing that makes this build a little unusual is the ethernet port. To that end, a USB port is also provided, hooked up to the uC with the cheap CP2102 USB bridge chip as per most Arduino-like designs. A rear-facing OLED display shows some useful debug information as well as the all important IP address that was assigned to the unit.Ĭontrol is performed with the ubiquitous ATMega328 microcontroller, with the Arduino software stack deployed, making uploading firmware a breeze. Leveraging the Trinamic TMC2208 stepper motor driver gives Ethersweep silky smooth and quiet motor control, which could be very important for some applications. The system can be closed loop, with both an end-stop input as well as an on-board AMS AS5600 magnetic rotary encoder (which senses the rotating magnetic field on the rear side of the motor assembly – clever!) giving the necessary feedback. The only physical connectivity, beside the motor, are ethernet and a power supply via the user friendly XT30 connector. The solution is named Ethersweep, and is a small PCB stack that sits on the rear of the common NEMA17-format stepper motor. Over on Hackaday.IO wanted a simple-to-use way to drive stepper motors, which could be quickly deployed in a wide variety of applications yet to be determined.

0 kommentar(er)

0 kommentar(er)